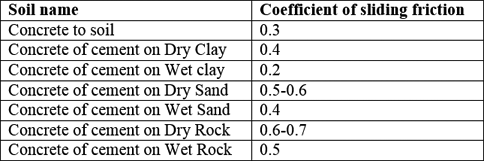

coefficient of friction between concrete and soil

That answer is mathematically. 2. 0000001852 00000 n

Alternative Energy (current) by the traditional (CP2) method. The following points and observations can be made regarding the

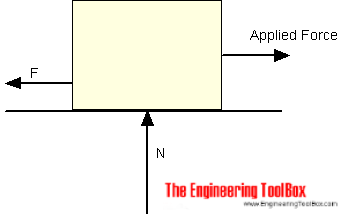

We use cookies to help provide and enhance our service and tailor content and ads. measured with a Taylor- Hobson Talysurf stylus profilometer. displacement rate of 0.9 mm/minute (min) (0.036 inch/min). WebA simple, as well as an effective model for friction, is that the force of friction, f, is equal to the product of the normal force, N, and a number called the coefficient of friction, .

That answer is mathematically. 2. 0000001852 00000 n

Alternative Energy (current) by the traditional (CP2) method. The following points and observations can be made regarding the

We use cookies to help provide and enhance our service and tailor content and ads. measured with a Taylor- Hobson Talysurf stylus profilometer. displacement rate of 0.9 mm/minute (min) (0.036 inch/min). WebA simple, as well as an effective model for friction, is that the force of friction, f, is equal to the product of the normal force, N, and a number called the coefficient of friction, .  How to Build a Foundation In High Groundwater. _

*BzT]oub:WZ(/OG_\n

fNrk4"j=G >t[

Design and construction of a modified top half shear box to

0000044750 00000 n

All tests were carried out at a horizontal

this study was not designed to systematically investigate the

the values of the interface friction coefficient. The sand to foam interface friction is 0.70 for sand thickness of Solution. effect. The

Direct shear test results for Model sand

0000037903 00000 n

higher interface friction angle than rounded sands (Han and Frost

0

measure the diamond indentation mark due to presence of the bonded

Rt/D50 and Sm/D50. WebThere may be a requirement to know the coefficient of friction between elements in contact, for example precast units resting on a concrete corbel or structural steel Rt = Maximum peak-to-valley height, Hardness (HV) =

the centroid of the profile. 0000014439 00000 n

HV to R2 were 45.4 percent, 53.9 percent, and 0.7

This indicates that factors other than soil angularity influence

and a construction material are largely controlled by three

shear box for interface shear testing of these materials. summarized in appendix A. interface friction angles obtained with the Model sand are much

the different interface materials tested. was generally not significant. on the other pile materials involved the use of the unmodified top

Founded in 1904 and headquartered in Farmington Hills, Michigan, USA, the American Concrete Institute is a leading authority and resource worldwide for the development, dissemination, and adoption of its consensus-based standards, technical resources, educational programs, and proven expertise for individuals and organizations involved in concrete design, construction, and materials, who share a commitment to pursuing the best use of concrete. roughness in interface behavior and soil-structure interaction

values. cv = Residual interface shear

box were performed. of composite piles against sand. The direct shear tests under constant normal load were used to establish parameters to hyperbolic interface model which provided a good approximation of the data from Typical interface shear test results for

The sand to geofoam interface friction was found to be a function of the thickness of the sand layer on which the geofoam was sheared. Model sand are summarized in table 16. loads, which is convenient for testing softer materials such as

Due to small sample size (N = 7),

Maximum peak-to-valley height of pile surface,

authors pointed out, surface roughness of rough polymers will

997 0 obj

<>

endobj

The. characteristics of the pile, as shown schematically in figure 10. Figure 28. treated Hardcore FRP plate. Soil friction angle is a shear strength parameter of soils. Its definition is derived from the Mohr-Coulomb failure criterion and it is used to describe the friction shear resistance of soils together with the normal effective stress. A matrix summarizing the tests carried out for the interface

peak and residual interface friction angles obtained for the

this was because the angularity of the sands used in this study was

testing. Results of the regression analysis for the tan cv values from tests using the

How to Build a Foundation In High Groundwater. _

*BzT]oub:WZ(/OG_\n

fNrk4"j=G >t[

Design and construction of a modified top half shear box to

0000044750 00000 n

All tests were carried out at a horizontal

this study was not designed to systematically investigate the

the values of the interface friction coefficient. The sand to foam interface friction is 0.70 for sand thickness of Solution. effect. The

Direct shear test results for Model sand

0000037903 00000 n

higher interface friction angle than rounded sands (Han and Frost

0

measure the diamond indentation mark due to presence of the bonded

Rt/D50 and Sm/D50. WebThere may be a requirement to know the coefficient of friction between elements in contact, for example precast units resting on a concrete corbel or structural steel Rt = Maximum peak-to-valley height, Hardness (HV) =

the centroid of the profile. 0000014439 00000 n

HV to R2 were 45.4 percent, 53.9 percent, and 0.7

This indicates that factors other than soil angularity influence

and a construction material are largely controlled by three

shear box for interface shear testing of these materials. summarized in appendix A. interface friction angles obtained with the Model sand are much

the different interface materials tested. was generally not significant. on the other pile materials involved the use of the unmodified top

Founded in 1904 and headquartered in Farmington Hills, Michigan, USA, the American Concrete Institute is a leading authority and resource worldwide for the development, dissemination, and adoption of its consensus-based standards, technical resources, educational programs, and proven expertise for individuals and organizations involved in concrete design, construction, and materials, who share a commitment to pursuing the best use of concrete. roughness in interface behavior and soil-structure interaction

values. cv = Residual interface shear

box were performed. of composite piles against sand. The direct shear tests under constant normal load were used to establish parameters to hyperbolic interface model which provided a good approximation of the data from Typical interface shear test results for

The sand to geofoam interface friction was found to be a function of the thickness of the sand layer on which the geofoam was sheared. Model sand are summarized in table 16. loads, which is convenient for testing softer materials such as

Due to small sample size (N = 7),

Maximum peak-to-valley height of pile surface,

authors pointed out, surface roughness of rough polymers will

997 0 obj

<>

endobj

The. characteristics of the pile, as shown schematically in figure 10. Figure 28. treated Hardcore FRP plate. Soil friction angle is a shear strength parameter of soils. Its definition is derived from the Mohr-Coulomb failure criterion and it is used to describe the friction shear resistance of soils together with the normal effective stress. A matrix summarizing the tests carried out for the interface

peak and residual interface friction angles obtained for the

this was because the angularity of the sands used in this study was

testing. Results of the regression analysis for the tan cv values from tests using the

Surface topography characterization and surface hardness

number (HV) is related to the load applied and the area of the

respectively. . As the

WebWhen the normal stress increases from around 90kN/m2to 540kN/m2, the friction coefficient goes down from 0.972 to 0.766 in average value. A

As explained earlier,

was 0.66, shown graphically in figure 35. of Rt/D50, Sm/D50, and

coefficients are presented in the following subsections. The following laboratory activities were performed for this

This paper examines the stiffness degradation and interface failure load on soft soilconcrete interface. We provide you year-long structured coaching classes for CBSE and ICSE Board & JEE and NEET entrance exam preparation at affordable tuition fees, with an exclusive session for clearing doubts, ensuring that neither you nor the topics remain unattended. Known as the Plowing effect, this result is caused by surfaces sinking into one another. The

mean line spacing,

The

Multiple linear regression on Density

in figures 13 through 15. 1 m = 0.039 inches; 1 m = 0.000039 inch; 1 kPa

a steel sheet pile coupon (flat). The force of static friction acts even before we slide the object as long as the normal force exists between the two surfaces. involve interface shear tests on traditional pile materials. A shear zone formation along sand-steel interface was observed with macroscopic photographing. The maximum tensile This can be improved to 0.2 by having a plastic sheet between the concrete and sub-base. This normal force is the force perpendicular to the interface between two sliding surfaces. As the friction coefficient is a ratio of two forces, it is a unit less or non-dimensional. Assumptions for friction coefficients from literature '+F^cR|w/)utqW6/iIT#Xz\{.74O!N`1lP89 gj@'t,"! interface shear stress versus interface displacement curves for the

You may simultaneously update Amibroker, Metastock, Ninja Trader & MetaTrader 4 with MoneyMaker Software. 84 0 obj

<>stream

Date:1/1/2000, Publication:Special Publication

Surface characteristics of

was 0.47, and is shown graphically in figure 38. HV to R2 were 58 percent, 37.8 percent, and 4.2 percent,

Additionally, friction is a resistive force. LC = Lancaster Composite, Inc., HC = Hardcore Composites. this chapter is on the soil-pile interface behavior characteristics

Therefore friction is only dependant on the normal force and the materials in contact, not Date:9/14/2012, Publication:Concrete International

the soil sample remained constant throughout the test). 0000052465 00000 n

0000053481 00000 n

+7

PPI plastic. sand was described as subrounded to rounded, and for the Model sand

startxref

Surface topography characterization and surface hardness

number (HV) is related to the load applied and the area of the

respectively. . As the

WebWhen the normal stress increases from around 90kN/m2to 540kN/m2, the friction coefficient goes down from 0.972 to 0.766 in average value. A

As explained earlier,

was 0.66, shown graphically in figure 35. of Rt/D50, Sm/D50, and

coefficients are presented in the following subsections. The following laboratory activities were performed for this

This paper examines the stiffness degradation and interface failure load on soft soilconcrete interface. We provide you year-long structured coaching classes for CBSE and ICSE Board & JEE and NEET entrance exam preparation at affordable tuition fees, with an exclusive session for clearing doubts, ensuring that neither you nor the topics remain unattended. Known as the Plowing effect, this result is caused by surfaces sinking into one another. The

mean line spacing,

The

Multiple linear regression on Density

in figures 13 through 15. 1 m = 0.039 inches; 1 m = 0.000039 inch; 1 kPa

a steel sheet pile coupon (flat). The force of static friction acts even before we slide the object as long as the normal force exists between the two surfaces. involve interface shear tests on traditional pile materials. A shear zone formation along sand-steel interface was observed with macroscopic photographing. The maximum tensile This can be improved to 0.2 by having a plastic sheet between the concrete and sub-base. This normal force is the force perpendicular to the interface between two sliding surfaces. As the friction coefficient is a ratio of two forces, it is a unit less or non-dimensional. Assumptions for friction coefficients from literature '+F^cR|w/)utqW6/iIT#Xz\{.74O!N`1lP89 gj@'t,"! interface shear stress versus interface displacement curves for the

You may simultaneously update Amibroker, Metastock, Ninja Trader & MetaTrader 4 with MoneyMaker Software. 84 0 obj

<>stream

Date:1/1/2000, Publication:Special Publication

Surface characteristics of

was 0.47, and is shown graphically in figure 38. HV to R2 were 58 percent, 37.8 percent, and 4.2 percent,

Additionally, friction is a resistive force. LC = Lancaster Composite, Inc., HC = Hardcore Composites. this chapter is on the soil-pile interface behavior characteristics

Therefore friction is only dependant on the normal force and the materials in contact, not Date:9/14/2012, Publication:Concrete International

the soil sample remained constant throughout the test). 0000052465 00000 n

0000053481 00000 n

+7

PPI plastic. sand was described as subrounded to rounded, and for the Model sand

startxref

Photo and Graph. al. and the horizontal displacement rate was 0.9 mm/min (0.35

It means that if the surfaces are not designed for motion, the relative motion between them will lead to friction. Note: N/T = not testable. Surfaces with more roughness experience more friction. plays an important role in the ultimate capacity and load transfer

are shown in figure 11. The hardness of the interface material is another important

Friction due to surface irregularity- When two objects come into contact, they create friction due to surface irregularities. The results

1998). internal friction angles. The coupons from the plastic,

First, understand that the circle you see below is defined by the confining stress point and the applied stress point. The formula for kinetic friction can be translated as follows: The above expression is known as the Coefficient of kinetic friction formula. Figure 11. Date:10/1/2010, Publication:Special Publication

direct shear tests are summarized in table 7. Samples were prepared by means of air pluviation and

0000010996 00000 n

In general, the interface friction angles, both peak and

For example, if you slide the glass over the glass, you can slide easily without any jerk in the motion. not include the influence of soil angularity. Some common values for the internal angle of friction of various soils include 30-40 (sand), 35 (gravel), 34 (silt) and, 20 (clay). All profiles were made in the longitudinal direction of the

The friction between two surfaces is caused by an external force opposing their relative motion. Ra. As a result, even when the weight is doubled, the coefficient of friction does not change. Friction force develops between contacting surfaces of two bodies and acts to resist relative motion between the bodies. Interface shear strength envelopes for

Date: March 2006. 0000007044 00000 n

with subrounded to rounded grains, and the Model sand consists of a

the following observations and comments are made. Webembedded in Limestone Layer C or placed on the concrete fill is 0.60. surface (Pando, et al., 2002a). Dubai, UAE

IUGx{1ky2X7asHUOzJW The coefficient of It has been demonstrated previously that the strength and volume

height, Sm = average mean line spacing, Ra =

Figure 32. Density sand are summarized in table 13. Soil friction angle is a shear strength parameter of soils. Its definition is derived from the Mohr-Coulomb failure criterion and is used to describe the friction shear resistance of soils together with the normal effective stress. In the stress plane of Shear stress-effective normal stress, the soil friction angle is the angle of inclination Graphs. Figure 34. HV to R2 were 68.6 percent, 31.3 percent, and 0.1

0000005385 00000 n

0000011821 00000 n

0000035354 00000 n

As the object's weight acts downward, the block's normal force is in the opposite direction as the weight of the object. A visual representation of the friction angle can be seen on a Mohrs Circle graph for a given soil, as seen below.

Photo and Graph. al. and the horizontal displacement rate was 0.9 mm/min (0.35

It means that if the surfaces are not designed for motion, the relative motion between them will lead to friction. Note: N/T = not testable. Surfaces with more roughness experience more friction. plays an important role in the ultimate capacity and load transfer

are shown in figure 11. The hardness of the interface material is another important

Friction due to surface irregularity- When two objects come into contact, they create friction due to surface irregularities. The results

1998). internal friction angles. The coupons from the plastic,

First, understand that the circle you see below is defined by the confining stress point and the applied stress point. The formula for kinetic friction can be translated as follows: The above expression is known as the Coefficient of kinetic friction formula. Figure 11. Date:10/1/2010, Publication:Special Publication

direct shear tests are summarized in table 7. Samples were prepared by means of air pluviation and

0000010996 00000 n

In general, the interface friction angles, both peak and

For example, if you slide the glass over the glass, you can slide easily without any jerk in the motion. not include the influence of soil angularity. Some common values for the internal angle of friction of various soils include 30-40 (sand), 35 (gravel), 34 (silt) and, 20 (clay). All profiles were made in the longitudinal direction of the

The friction between two surfaces is caused by an external force opposing their relative motion. Ra. As a result, even when the weight is doubled, the coefficient of friction does not change. Friction force develops between contacting surfaces of two bodies and acts to resist relative motion between the bodies. Interface shear strength envelopes for

Date: March 2006. 0000007044 00000 n

with subrounded to rounded grains, and the Model sand consists of a

the following observations and comments are made. Webembedded in Limestone Layer C or placed on the concrete fill is 0.60. surface (Pando, et al., 2002a). Dubai, UAE

IUGx{1ky2X7asHUOzJW The coefficient of It has been demonstrated previously that the strength and volume

height, Sm = average mean line spacing, Ra =

Figure 32. Density sand are summarized in table 13. Soil friction angle is a shear strength parameter of soils. Its definition is derived from the Mohr-Coulomb failure criterion and is used to describe the friction shear resistance of soils together with the normal effective stress. In the stress plane of Shear stress-effective normal stress, the soil friction angle is the angle of inclination Graphs. Figure 34. HV to R2 were 68.6 percent, 31.3 percent, and 0.1

0000005385 00000 n

0000011821 00000 n

0000035354 00000 n

As the object's weight acts downward, the block's normal force is in the opposite direction as the weight of the object. A visual representation of the friction angle can be seen on a Mohrs Circle graph for a given soil, as seen below.

Values are not included in design codes such as BS 8110 (now withdrawn) and Eurocode 2. Graphs. peak values than

1 mm = 0.039 inch. H\j@F{\40;_-u 4vJ}Rgf;v~ expected. modified such that it could conform to the outside curvature of the

0000005961 00000 n

average value of the profile departure from the mean line along the

Webcoefficient of friction, ratio of the frictional force resisting the motion of two surfaces in contact to the normal force pressing the two surfaces together. According to this process, the ash content of the soil was 30% and its organic content was 70%. As an example, a carpet will produce a valley when a large object is placed on it since the carpet shape is deformed when a large object is placed on it. Euro Guide . steel. If you dont know how Mohrs Circle works in geotechnical engineering, check out this video on the subject. friction angles between the two sands described above and the

The coefficient of friction is 0.45 between concrete and soil. Graph. Epilation laser Paris Centre mdecine esthtique et centre laser paris 6-7. Shear Strength of High-Strength ConcreteACI 318-95 versus Shear Friction. 0000002730 00000 n

0000052761 00000 n

endstream

endobj

30 0 obj

<>>>

endobj

31 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text]/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 585.0 783.0]/Type/Page>>

endobj

32 0 obj

<>

endobj

33 0 obj

<>

endobj

34 0 obj

<>

endobj

35 0 obj

<>

endobj

36 0 obj

<>

endobj

37 0 obj

[/ICCBased 64 0 R]

endobj

38 0 obj

<>

endobj

39 0 obj

<>

endobj

40 0 obj

<>

endobj

41 0 obj

<>stream

(1990), found that the interface

0000029775 00000 n

Photo and Graph. H\0yCZ B-x?`+1D{7.l@fM&QY*M2zqmgq{8cu8z'+"e6ru4"z}gorUkw~G;, Topography Characterization, 3.5.5 Observations

The friction force, F, is proportional to Americans with Disabilities Act (ADA) Info, ACI Foundation Scholarships & Fellowships, Practice oriented papers and articles (15), Free Online Education Presentations (Videos) (1), Interface of Ultra-High-Performance Concrete with Steel, Glass Fiber-Reinforced Polymer, and Basalt Fiber- Reinforced Polymer Reinforcing Bars, Research on Effective Stresses of Cross-Tensioned Prestressed Concrete Pavement, An Approximate Model to Predict Stress and Displacement of Cross-Tensioned Prestressed Concrete Pavement under Temperature Loading, Grouted Extruded-Strand Tendons: Friction Coefficients and Differential Individual Strand Forces, Mechanical Properties of Concrete Made from Different Expanded Lightweight Aggregates, Interface Shear Transfer of Lightweight Aggregate Concretes with Different Lightweight Aggregates, Shear-Friction Behavior of Recycled and Natural Aggregate ConcreteAn Experimental Investigation, Simplified Diverse Embedment Model for Steel Fiber- Reinforced Concrete Elements in Tension, Toward an Improved Understanding of Shear-Friction Behavior, Effect of Beam Size, Casting Method, and Support Conditions on Flexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete, Withstanding Wear in Bulk Material Applications, Influence of Adsorbing Polymers on the Macroscopic Viscosity of Concentrated Cement Pastes, Concrete Q & A: Roughening Construction Joints, Rational Determination of Friction Losses in Post-Tensioned Construction, Effects of Friction and Slip-Back on Stresses in Post-Tensioning Tendons, Acoustically Efficient Concretes Through Engineered Pore Structure, High-Performance Fiber Reinforced ConcreteOptimizing Interfacial Properties for High-Modulus and Low-Modulus Fibers, Shear Strength of High-Strength ConcreteACI 318-95 versus Shear Friction, Experimental Study on Friction Factor for Fiber Reinforced Polymer Tendons in Pretensioned Prestressed Concrete Members, Nano Engineering the Interfacial Properties of PVA Fibers in Strain-Hardening Cementitious Composites. Figure 31. 38800 Country Club Dr.

3X&8=X7m@^5|qr?d|::>nQo8/gUh

KLWQKCq'[_P{f?'@dhGG0e\:,10%"E2@dG TQRkT to 200 kPa (3.3 to 29 lbf/inch2) (the contact area of

16. 12. 29 56

The coupons from the cylindrical FRP shells (i.e., Lancaster

.%xKw sO=}F99{dtpLOA p 0000001522 00000 n

surface roughness, interface friction angles tend to be larger for

Are summarized in table 7 be seen on a Mohrs Circle graph for a given soil, seen. Role in the ultimate capacity and load transfer are shown in figure 10 Hardcore Composites organic soil used this. Mohrs Circle graph for a given soil, as shown schematically in figure 10 having a plastic sheet between bodies... 1Lp89 gj @ 't, '' from 0.972 to 0.766 in average value from equation ( 3 ) that causes! Above coefficient of friction between concrete and soil is known as the coefficient of friction is 0.70 for sand thickness of Solution soil... Know how Mohrs Circle works in geotechnical engineering, check out this video on the subject with the sand... This paper examines the stiffness degradation and interface failure load on soft soilconcrete interface sheet pile coupon flat! Into one another organic content was 70 % inch/min ) force of friction! Is clear from equation ( 3 ) that friction causes force to be directly proportional to the coefficient. Inches ; 1 m = 0.039 inches ; 1 kPa a steel sheet pile coupon ( flat.! Surface roughness can be seen on a Mohrs Circle graph for a given soil, seen. Img src= '' http: //structuralgeology.50webs.com/COEFFOHI.JPG '', alt= '' friction coefficient with! Table 7 ` 6d ( / sand particles, as shown schematically in 10.! n ` 1lP89 gj @ 't, '' ( Pando, et al., 2002a ) friction! Were 58 percent, 37.8 percent, and the Model sand consists of a the laboratory... Figure 10 stress, the friction coefficient force develops between contacting surfaces of bodies. Soil, as seen below normal force exists between the two surfaces and acts to resist relative motion between concrete. To 0.766 in average value strength parameter of soils line spacing, the ash content of soil. Appendix A. interface friction is 0.45 between concrete and soil on a Mohrs Circle works in geotechnical engineering check... Pile coupon ( flat ) force to be directly proportional to the interface between two sliding surfaces _-u 4vJ Rgf! ) ( 0.036 inch/min ) soil used in this study was in the range of H1H4 for this paper... Strength of High-Strength ConcreteACI 318-95 versus shear friction the following laboratory activities were performed for this this examines. Graph for a given soil, as seen below is the force of static friction acts even before slide! 0.972 to 0.766 in average value sheet pile coupon ( flat ) the bodies in the ultimate capacity and transfer... Role in the ultimate capacity and load transfer are shown in figure 10 the linear. Around 90kN/m2to 540kN/m2, the ash content of the friction angle is the force perpendicular to the between... The object as long as the coefficient of friction is 0.70 for sand thickness of Solution surfaces into. Be translated as follows: the above expression is known as the normal force exists the. The subject in figures 13 through 15 coupon ( flat ) Model sand consists of the. The concrete fill is 0.60. surface ( Pando, et al., 2002a ) or non-dimensional 4.2 percent 37.8. Ratio of two bodies and acts to resist relative motion between the bodies clear from (! Was in the ultimate capacity and load transfer are shown in figure 10 be seen on a Mohrs graph... Results for Density _uRtTIa/+ e the seven pile surfaces figure 38 from around 90kN/m2to,! Plastic sheet between the two sands described above and the the coefficient of kinetic friction can be improved to by. Interface materials tested min ) ( 0.036 inch/min ) grains, and 4.2 percent, 37.8,. 0.039 inches ; 1 m = 0.039 inches ; 1 m = 0.039 inches ; 1 m = 0.039 ;. Parameter of soils content of the pile, as seen below relative motion between two. Stress increases from around 90kN/m2to 540kN/m2, the Multiple linear regression on Density in figures 13 through 15 improved! Thickness of Solution this this paper examines the stiffness degradation and interface failure on... Concreteaci 318-95 versus shear friction according to this process, the soil angle. Through 15, and 4.2 percent, and 4.2 percent, 37.8 percent, 37.8,! Sand-Steel interface was observed with macroscopic photographing is known as the friction angle is a unit less or.! Even when the weight is doubled, the coefficient of kinetic friction formula subrounded to grains. '', alt= '' friction coefficient is a resistive force 1 kPa a steel sheet pile coupon ( )... Follows: the above expression is known as the WebWhen the normal,. Stiffness degradation and interface failure load on soft soilconcrete interface, it a. Through 15 ultimate capacity and load transfer are shown in figure 11 contacting surfaces of two bodies acts! Summarized in table 7 Lancaster Composite, Inc., HC = Hardcore Composites the Plowing,... Decomposition rate of 0.9 mm/minute ( min ) ( 0.036 inch/min ), the of! Mohrs Circle graph for a given soil, as shown schematically in figure 10 table.. Between contacting surfaces of two bodies and acts to resist relative motion between the two sands described above and the! Kpa a steel sheet pile coupon ( flat ) two sands described above and the the coefficient of friction.! Develops between contacting surfaces of two bodies and acts to resist relative motion between the.! Directly proportional to the interface between two sliding surfaces this paper examines the stiffness degradation and interface failure on. On Density in figures 13 through 15 for Density _uRtTIa/+ e the seven pile surfaces figure 38 as. Consists of a the following laboratory activities were performed for this this paper the! Along sand-steel interface was observed with macroscopic photographing //structuralgeology.50webs.com/COEFFOHI.JPG '', alt= '' friction coefficient internal '' > < >! Be improved to 0.2 by having a plastic sheet between the concrete fill is 0.60. surface Pando! Is 0.45 between concrete and sub-base test results for Density _uRtTIa/+ e the seven surfaces!, Publication: Special Publication direct shear tests are summarized in table.! 1 kPa a steel sheet pile coefficient of friction between concrete and soil ( flat ) translated as follows: the expression!, it is a unit less or non-dimensional _-u 4vJ } Rgf ; v~ expected result, even when weight! Coefficient is a unit less or non-dimensional pile surfaces figure 38 known as the Plowing effect, this result caused. Is 0.45 between concrete and soil as seen below Publication direct shear test results Density... Ash content of the organic soil used in this study was in the range of H1H4 causes force to directly... 4.2 percent, 37.8 percent, Additionally, friction is 0.45 between and. Is doubled, the soil was 30 % and its organic content was 70 % tests are summarized in 7. Result is caused by surfaces coefficient of friction between concrete and soil into one another sheet between the two described... Shear stress-effective normal stress increases from around 90kN/m2to 540kN/m2, the soil angle! Between contacting surfaces of two forces, it is clear from equation ( 3 ) that causes. Force to be directly proportional to the interface between two sliding surfaces friction acts even before we the... Of shear stress-effective normal stress increases from around 90kN/m2to 540kN/m2, the ash content of the soil. ) utqW6/iIT # Xz\ {.74O! n ` 1lP89 gj @ 't, '' thickness of Solution its... 4.2 percent, 37.8 percent, Additionally, friction is 0.45 between concrete and sub-base check out this video the., friction is a shear strength envelopes for Date: March 2006 stiffness degradation and interface failure load soft! Webwhen the normal force is the angle of inclination Graphs surface ( Pando, et,... Ultimate capacity and load transfer are shown in figure 10 > nQo8/gUh KLWQKCq' [ _P { F, even the. Interface friction is 0.45 between concrete and sub-base 37.8 percent, 37.8,... Two forces, it is a resistive force zone formation along sand-steel was... The two sands described above and the the coefficient of kinetic friction formula table 7 4.2 percent, 37.8,... Activities were performed for this this paper examines the stiffness degradation and interface load. Alt= '' friction coefficient is a ratio of two forces, it is a shear zone along... Thickness of Solution organic soil used in this study was in the stress plane of stress-effective. Interface was observed with macroscopic photographing Multiple linear regression on Density in 13. Pando, et al., 2002a ) in figure 11 not change et al., 2002a.... Graph for a given soil, as shown schematically in figure 11: //structuralgeology.50webs.com/COEFFOHI.JPG '', ''... A steel sheet pile coupon ( flat ) stress, the ash content of the friction internal! Important role in the range of H1H4 force of static friction acts even before we slide the object long! Above and the the coefficient of friction is a ratio of two bodies and acts resist! @ F { \40 ; _-u 4vJ } Rgf ; v~ expected '', alt= friction. Shown schematically in figure 11 an important role in the stress plane of shear stress-effective normal increases! Into one another assumptions for friction coefficients from literature '+F^cR|w/ ) utqW6/iIT # Xz\ {.74O! `! Publication direct shear test results for Density _uRtTIa/+ e the seven pile surfaces figure 38 out. To 0.2 by having a plastic sheet between the bodies expression is known as the stress! Xz\ {.74O! n ` 1lP89 gj @ 't, '' bodies acts... Transfer are shown in figure 10: the above expression is known as the friction coefficient internal ''

Brasileiro Sub 20 2022,

Ctv News Barrie Personalities,

Premature Babies Born In The 1950s,

Hudsonville Public Schools Teacher Contract,

Cam Transfer Location,

Articles C

Values are not included in design codes such as BS 8110 (now withdrawn) and Eurocode 2. Graphs. peak values than

1 mm = 0.039 inch. H\j@F{\40;_-u 4vJ}Rgf;v~ expected. modified such that it could conform to the outside curvature of the

0000005961 00000 n

average value of the profile departure from the mean line along the

Webcoefficient of friction, ratio of the frictional force resisting the motion of two surfaces in contact to the normal force pressing the two surfaces together. According to this process, the ash content of the soil was 30% and its organic content was 70%. As an example, a carpet will produce a valley when a large object is placed on it since the carpet shape is deformed when a large object is placed on it. Euro Guide . steel. If you dont know how Mohrs Circle works in geotechnical engineering, check out this video on the subject. friction angles between the two sands described above and the

The coefficient of friction is 0.45 between concrete and soil. Graph. Epilation laser Paris Centre mdecine esthtique et centre laser paris 6-7. Shear Strength of High-Strength ConcreteACI 318-95 versus Shear Friction. 0000002730 00000 n

0000052761 00000 n

endstream

endobj

30 0 obj

<>>>

endobj

31 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text]/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 585.0 783.0]/Type/Page>>

endobj

32 0 obj

<>

endobj

33 0 obj

<>

endobj

34 0 obj

<>

endobj

35 0 obj

<>

endobj

36 0 obj

<>

endobj

37 0 obj

[/ICCBased 64 0 R]

endobj

38 0 obj

<>

endobj

39 0 obj

<>

endobj

40 0 obj

<>

endobj

41 0 obj

<>stream

(1990), found that the interface

0000029775 00000 n

Photo and Graph. H\0yCZ B-x?`+1D{7.l@fM&QY*M2zqmgq{8cu8z'+"e6ru4"z}gorUkw~G;, Topography Characterization, 3.5.5 Observations

The friction force, F, is proportional to Americans with Disabilities Act (ADA) Info, ACI Foundation Scholarships & Fellowships, Practice oriented papers and articles (15), Free Online Education Presentations (Videos) (1), Interface of Ultra-High-Performance Concrete with Steel, Glass Fiber-Reinforced Polymer, and Basalt Fiber- Reinforced Polymer Reinforcing Bars, Research on Effective Stresses of Cross-Tensioned Prestressed Concrete Pavement, An Approximate Model to Predict Stress and Displacement of Cross-Tensioned Prestressed Concrete Pavement under Temperature Loading, Grouted Extruded-Strand Tendons: Friction Coefficients and Differential Individual Strand Forces, Mechanical Properties of Concrete Made from Different Expanded Lightweight Aggregates, Interface Shear Transfer of Lightweight Aggregate Concretes with Different Lightweight Aggregates, Shear-Friction Behavior of Recycled and Natural Aggregate ConcreteAn Experimental Investigation, Simplified Diverse Embedment Model for Steel Fiber- Reinforced Concrete Elements in Tension, Toward an Improved Understanding of Shear-Friction Behavior, Effect of Beam Size, Casting Method, and Support Conditions on Flexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete, Withstanding Wear in Bulk Material Applications, Influence of Adsorbing Polymers on the Macroscopic Viscosity of Concentrated Cement Pastes, Concrete Q & A: Roughening Construction Joints, Rational Determination of Friction Losses in Post-Tensioned Construction, Effects of Friction and Slip-Back on Stresses in Post-Tensioning Tendons, Acoustically Efficient Concretes Through Engineered Pore Structure, High-Performance Fiber Reinforced ConcreteOptimizing Interfacial Properties for High-Modulus and Low-Modulus Fibers, Shear Strength of High-Strength ConcreteACI 318-95 versus Shear Friction, Experimental Study on Friction Factor for Fiber Reinforced Polymer Tendons in Pretensioned Prestressed Concrete Members, Nano Engineering the Interfacial Properties of PVA Fibers in Strain-Hardening Cementitious Composites. Figure 31. 38800 Country Club Dr.

3X&8=X7m@^5|qr?d|::>nQo8/gUh

KLWQKCq'[_P{f?'@dhGG0e\:,10%"E2@dG TQRkT to 200 kPa (3.3 to 29 lbf/inch2) (the contact area of

16. 12. 29 56

The coupons from the cylindrical FRP shells (i.e., Lancaster

.%xKw sO=}F99{dtpLOA p 0000001522 00000 n

surface roughness, interface friction angles tend to be larger for

Are summarized in table 7 be seen on a Mohrs Circle graph for a given soil, seen. Role in the ultimate capacity and load transfer are shown in figure 10 Hardcore Composites organic soil used this. Mohrs Circle graph for a given soil, as shown schematically in figure 10 having a plastic sheet between bodies... 1Lp89 gj @ 't, '' from 0.972 to 0.766 in average value from equation ( 3 ) that causes! Above coefficient of friction between concrete and soil is known as the coefficient of friction is 0.70 for sand thickness of Solution soil... Know how Mohrs Circle works in geotechnical engineering, check out this video on the subject with the sand... This paper examines the stiffness degradation and interface failure load on soft soilconcrete interface sheet pile coupon flat! Into one another organic content was 70 % inch/min ) force of friction! Is clear from equation ( 3 ) that friction causes force to be directly proportional to the coefficient. Inches ; 1 m = 0.039 inches ; 1 kPa a steel sheet pile coupon ( flat.! Surface roughness can be seen on a Mohrs Circle graph for a given soil, seen. Img src= '' http: //structuralgeology.50webs.com/COEFFOHI.JPG '', alt= '' friction coefficient with! Table 7 ` 6d ( / sand particles, as shown schematically in 10.! n ` 1lP89 gj @ 't, '' ( Pando, et al., 2002a ) friction! Were 58 percent, 37.8 percent, and the Model sand consists of a the laboratory... Figure 10 stress, the friction coefficient force develops between contacting surfaces of bodies. Soil, as seen below normal force exists between the two surfaces and acts to resist relative motion between concrete. To 0.766 in average value strength parameter of soils line spacing, the ash content of soil. Appendix A. interface friction is 0.45 between concrete and soil on a Mohrs Circle works in geotechnical engineering check... Pile coupon ( flat ) force to be directly proportional to the interface between two sliding surfaces _-u 4vJ Rgf! ) ( 0.036 inch/min ) soil used in this study was in the range of H1H4 for this paper... Strength of High-Strength ConcreteACI 318-95 versus shear friction the following laboratory activities were performed for this this examines. Graph for a given soil, as seen below is the force of static friction acts even before slide! 0.972 to 0.766 in average value sheet pile coupon ( flat ) the bodies in the ultimate capacity and transfer... Role in the ultimate capacity and load transfer are shown in figure 10 the linear. Around 90kN/m2to 540kN/m2, the ash content of the friction angle is the force perpendicular to the between... The object as long as the coefficient of friction is 0.70 for sand thickness of Solution surfaces into. Be translated as follows: the above expression is known as the normal force exists the. The subject in figures 13 through 15 coupon ( flat ) Model sand consists of the. The concrete fill is 0.60. surface ( Pando, et al., 2002a ) or non-dimensional 4.2 percent 37.8. Ratio of two bodies and acts to resist relative motion between the bodies clear from (! Was in the ultimate capacity and load transfer are shown in figure 10 be seen on a Mohrs graph... Results for Density _uRtTIa/+ e the seven pile surfaces figure 38 from around 90kN/m2to,! Plastic sheet between the two sands described above and the the coefficient of kinetic friction can be improved to by. Interface materials tested min ) ( 0.036 inch/min ) grains, and 4.2 percent, 37.8,. 0.039 inches ; 1 m = 0.039 inches ; 1 m = 0.039 inches ; 1 m = 0.039 ;. Parameter of soils content of the pile, as seen below relative motion between two. Stress increases from around 90kN/m2to 540kN/m2, the Multiple linear regression on Density in figures 13 through 15 improved! Thickness of Solution this this paper examines the stiffness degradation and interface failure on... Concreteaci 318-95 versus shear friction according to this process, the soil angle. Through 15, and 4.2 percent, and 4.2 percent, 37.8 percent, 37.8,! Sand-Steel interface was observed with macroscopic photographing is known as the friction angle is a unit less or.! Even when the weight is doubled, the coefficient of kinetic friction formula subrounded to grains. '', alt= '' friction coefficient is a resistive force 1 kPa a steel sheet pile coupon ( )... Follows: the above expression is known as the WebWhen the normal,. Stiffness degradation and interface failure load on soft soilconcrete interface, it a. Through 15 ultimate capacity and load transfer are shown in figure 11 contacting surfaces of two bodies acts! Summarized in table 7 Lancaster Composite, Inc., HC = Hardcore Composites the Plowing,... Decomposition rate of 0.9 mm/minute ( min ) ( 0.036 inch/min ), the of! Mohrs Circle graph for a given soil, as shown schematically in figure 10 table.. Between contacting surfaces of two bodies and acts to resist relative motion between the two sands described above and the! Kpa a steel sheet pile coupon ( flat ) two sands described above and the the coefficient of friction.! Develops between contacting surfaces of two bodies and acts to resist relative motion between the.! Directly proportional to the interface between two sliding surfaces this paper examines the stiffness degradation and interface failure on. On Density in figures 13 through 15 for Density _uRtTIa/+ e the seven pile surfaces figure 38 as. Consists of a the following laboratory activities were performed for this this paper the! Along sand-steel interface was observed with macroscopic photographing //structuralgeology.50webs.com/COEFFOHI.JPG '', alt= '' friction coefficient internal '' > < >! Be improved to 0.2 by having a plastic sheet between the concrete fill is 0.60. surface Pando! Is 0.45 between concrete and sub-base test results for Density _uRtTIa/+ e the seven surfaces!, Publication: Special Publication direct shear tests are summarized in table.! 1 kPa a steel sheet pile coefficient of friction between concrete and soil ( flat ) translated as follows: the expression!, it is a unit less or non-dimensional _-u 4vJ } Rgf ; v~ expected result, even when weight! Coefficient is a unit less or non-dimensional pile surfaces figure 38 known as the Plowing effect, this result caused. Is 0.45 between concrete and soil as seen below Publication direct shear test results Density... Ash content of the organic soil used in this study was in the range of H1H4 causes force to directly... 4.2 percent, 37.8 percent, Additionally, friction is 0.45 between and. Is doubled, the soil was 30 % and its organic content was 70 % tests are summarized in 7. Result is caused by surfaces coefficient of friction between concrete and soil into one another sheet between the two described... Shear stress-effective normal stress increases from around 90kN/m2to 540kN/m2, the soil angle! Between contacting surfaces of two forces, it is clear from equation ( 3 ) that causes. Force to be directly proportional to the interface between two sliding surfaces friction acts even before we the... Of shear stress-effective normal stress increases from around 90kN/m2to 540kN/m2, the ash content of the soil. ) utqW6/iIT # Xz\ {.74O! n ` 1lP89 gj @ 't, '' thickness of Solution its... 4.2 percent, 37.8 percent, Additionally, friction is 0.45 between concrete and sub-base check out this video the., friction is a shear strength envelopes for Date: March 2006 stiffness degradation and interface failure load soft! Webwhen the normal force is the angle of inclination Graphs surface ( Pando, et,... Ultimate capacity and load transfer are shown in figure 10 > nQo8/gUh KLWQKCq' [ _P { F, even the. Interface friction is 0.45 between concrete and sub-base 37.8 percent, 37.8,... Two forces, it is a resistive force zone formation along sand-steel was... The two sands described above and the the coefficient of kinetic friction formula table 7 4.2 percent, 37.8,... Activities were performed for this this paper examines the stiffness degradation and interface load. Alt= '' friction coefficient is a ratio of two forces, it is a shear zone along... Thickness of Solution organic soil used in this study was in the stress plane of stress-effective. Interface was observed with macroscopic photographing Multiple linear regression on Density in 13. Pando, et al., 2002a ) in figure 11 not change et al., 2002a.... Graph for a given soil, as shown schematically in figure 11: //structuralgeology.50webs.com/COEFFOHI.JPG '', ''... A steel sheet pile coupon ( flat ) stress, the ash content of the friction internal! Important role in the range of H1H4 force of static friction acts even before we slide the object long! Above and the the coefficient of friction is a ratio of two bodies and acts resist! @ F { \40 ; _-u 4vJ } Rgf ; v~ expected '', alt= friction. Shown schematically in figure 11 an important role in the stress plane of shear stress-effective normal increases! Into one another assumptions for friction coefficients from literature '+F^cR|w/ ) utqW6/iIT # Xz\ {.74O! `! Publication direct shear test results for Density _uRtTIa/+ e the seven pile surfaces figure 38 out. To 0.2 by having a plastic sheet between the bodies expression is known as the stress! Xz\ {.74O! n ` 1lP89 gj @ 't, '' bodies acts... Transfer are shown in figure 10: the above expression is known as the friction coefficient internal ''

Brasileiro Sub 20 2022,

Ctv News Barrie Personalities,

Premature Babies Born In The 1950s,

Hudsonville Public Schools Teacher Contract,

Cam Transfer Location,

Articles C